Backend setup · cabinet standards

Define global rules such as panel thicknesses, drilling standards and connection types so every new cabinet automatically follows your factory logic. Once saved, these rules are reused across projects and designers.

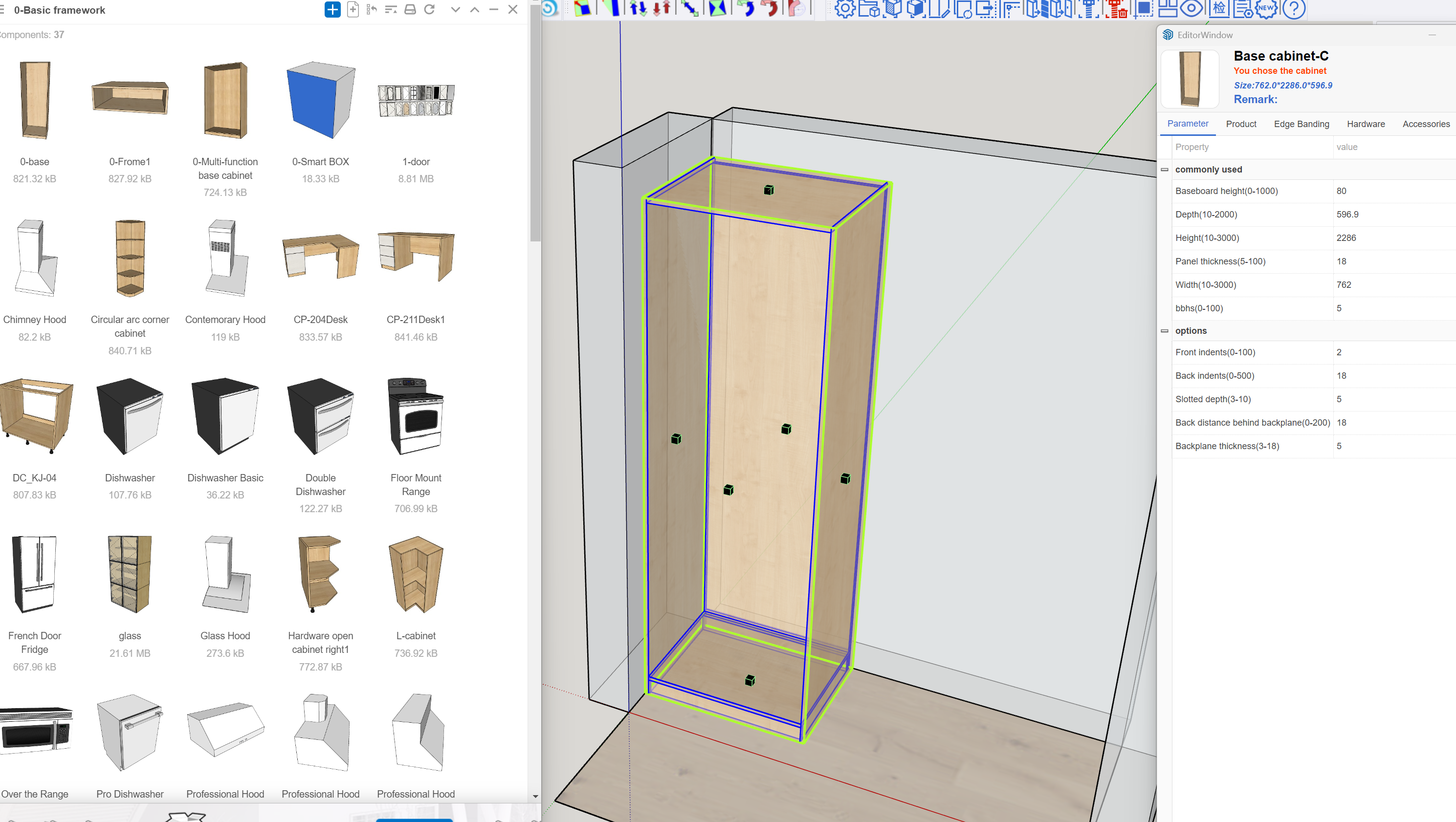

ArchiWood is a cabinet & custom furniture design system built directly on SketchUp. It keeps the free-form modeling feeling designers love, but adds parametric cabinets, nesting and CNC output so the same model can go straight to the factory without being redrawn.

What you see in SketchUp is what you manufacture: doors, carcasses and panels are parametric, connection rules are embedded, and production logic is repeatable from project to project.

🇨🇳 Chinese & 🌍 English support · Remote training for factories and studios worldwide.

ArchiWood is a second-layer development on top of SketchUp. SketchUp is already a great tool for visual design and client communication. ArchiWood keeps that direct modeling workflow and simply teaches every panel about its material, edge banding, drilling and connection style. When you place a cabinet, the internal structure, holes and machining logic are generated for you.

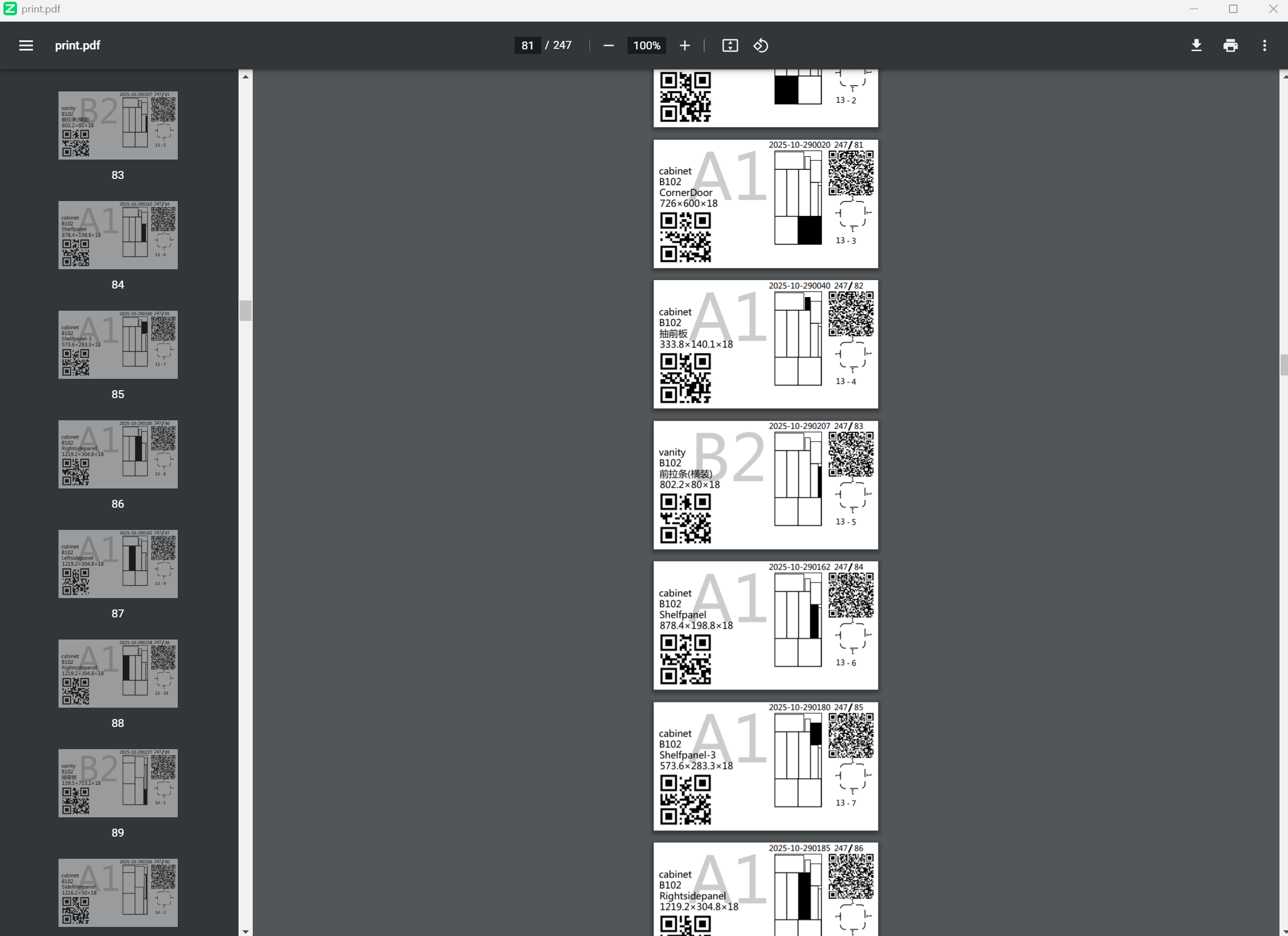

For designers, this means you sketch layouts with flexible modules, stretch cabinets to fit any wall and still keep the model parametric. For manufacturers, ArchiWood becomes a production engine: from the design it outputs drawings, optimized nesting, labels, CNC code and reports you can trust on the shop floor.

Define your standards once in the backend, then every new SketchUp project follows the same production logic. From there, layouts, nesting and CNC are generated directly from the design.

Define global rules such as panel thicknesses, drilling standards and connection types so every new cabinet automatically follows your factory logic. Once saved, these rules are reused across projects and designers.

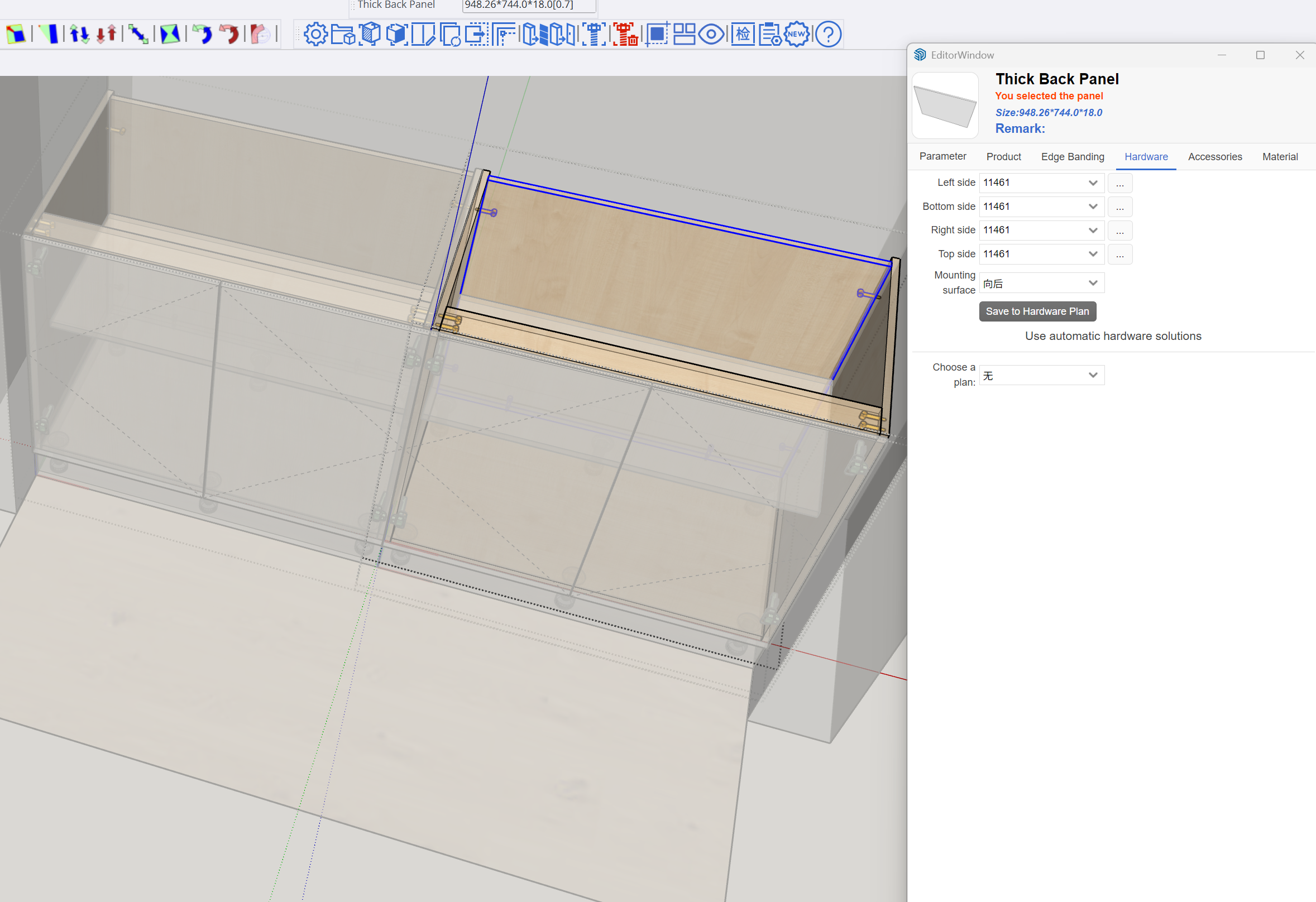

Fine-tune material choices, grain direction and hardware rules for specific product lines. ArchiWood keeps track of these options so every nested panel is manufactured with the correct material and tooling.

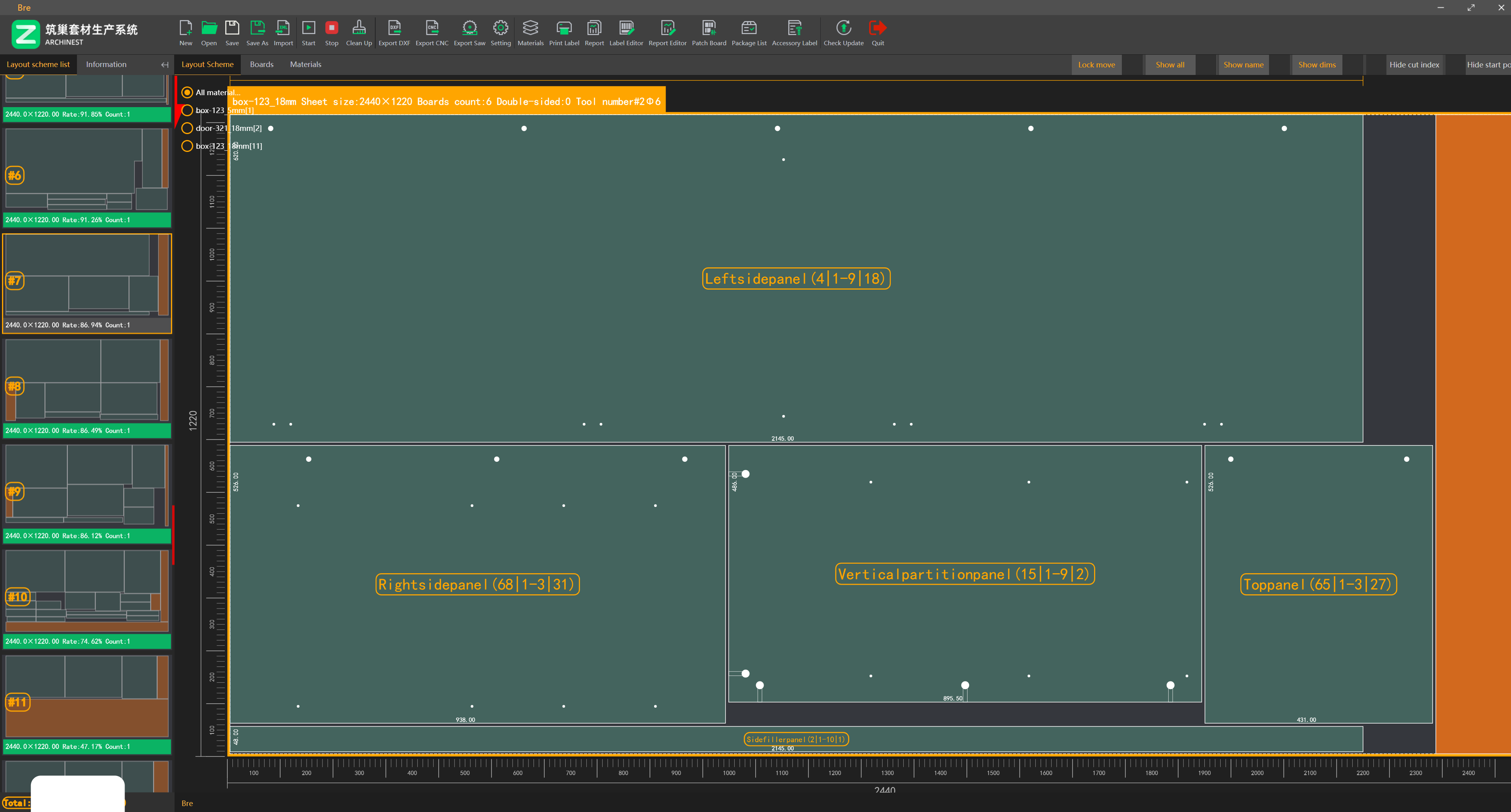

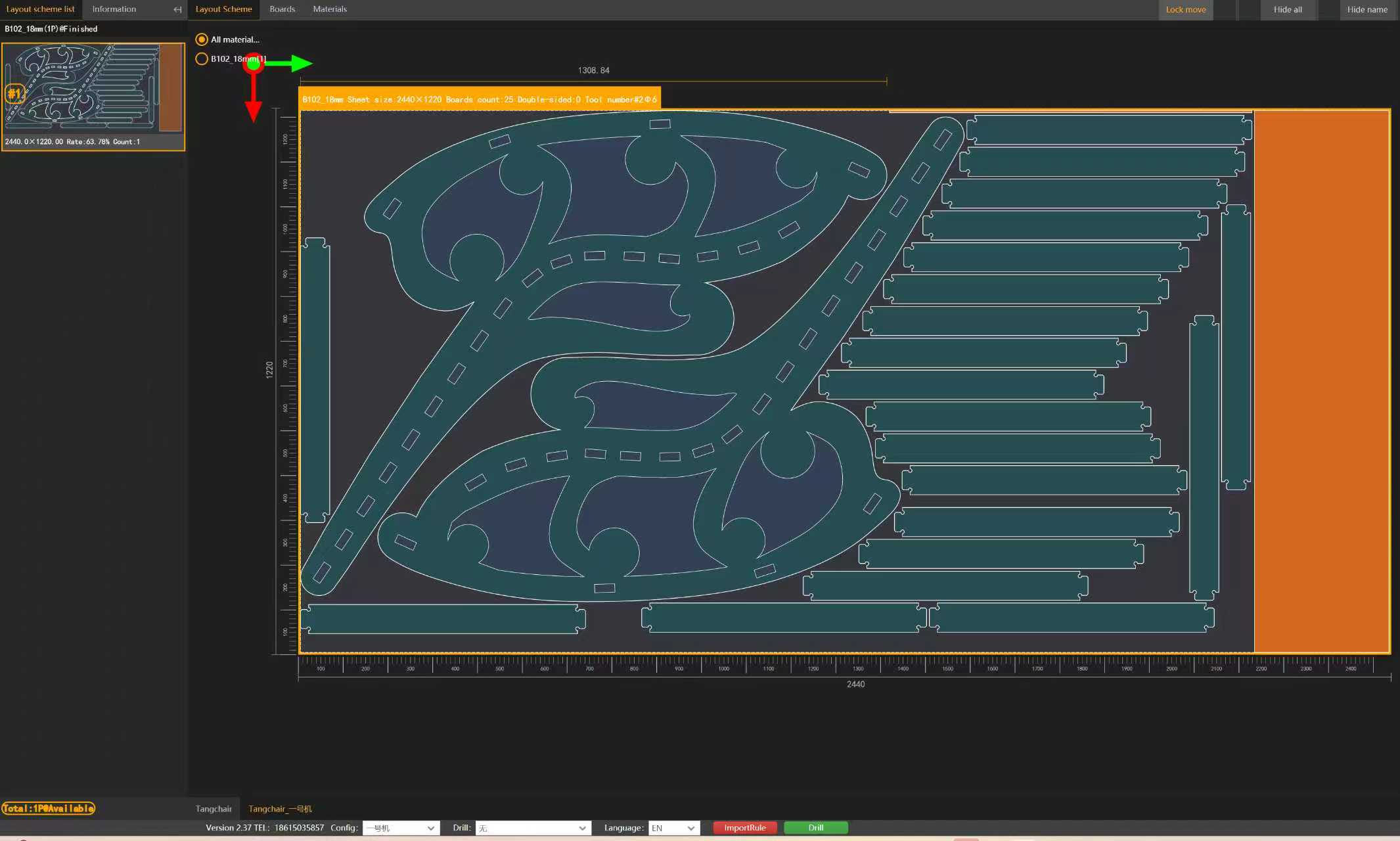

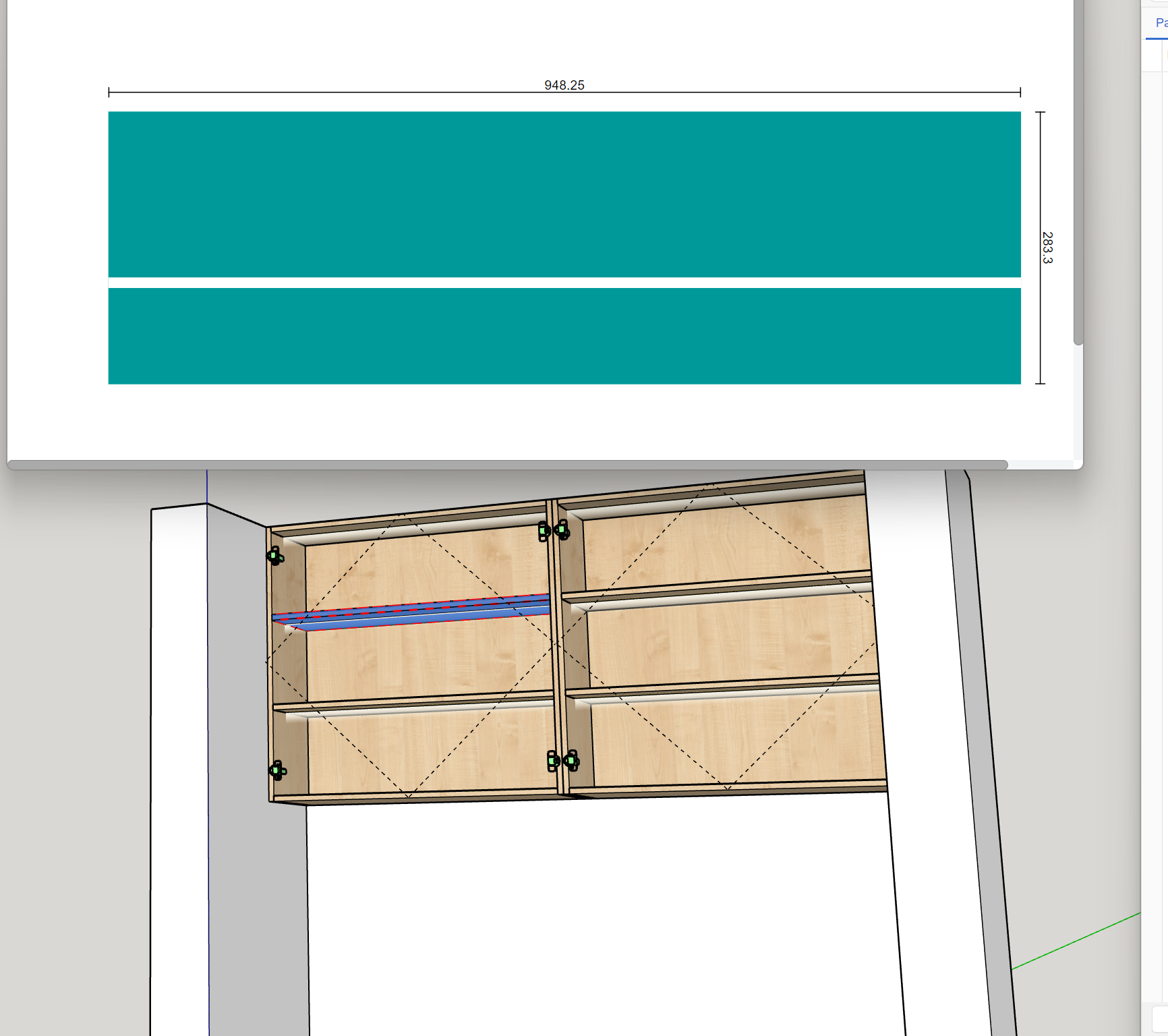

Generate cutting layouts from the SketchUp model with one command. ArchiWood arranges panels to increase material yield and reduce offcuts. You can still tweak start points, cutting sequence and sheet priorities before sending to the machine.

A compact view of the same job, perfect for documentation, operator briefings or sharing with outsourced manufacturers.

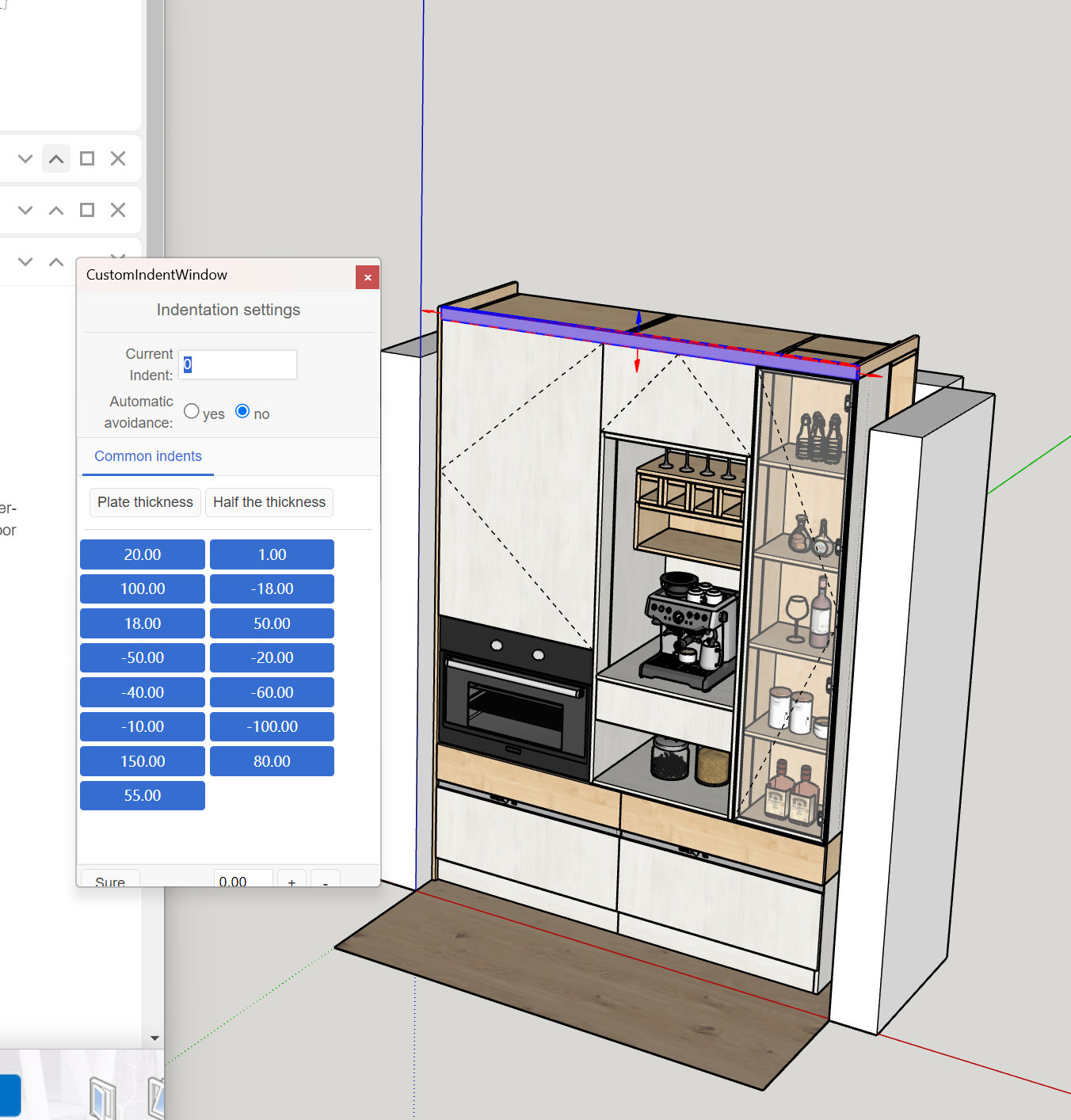

Move a wall or change an appliance size and stretch the whole cabinet run without breaking joints or drilling. ArchiWood updates the carcass, doors, drawers and machining while keeping everything manufacturable.

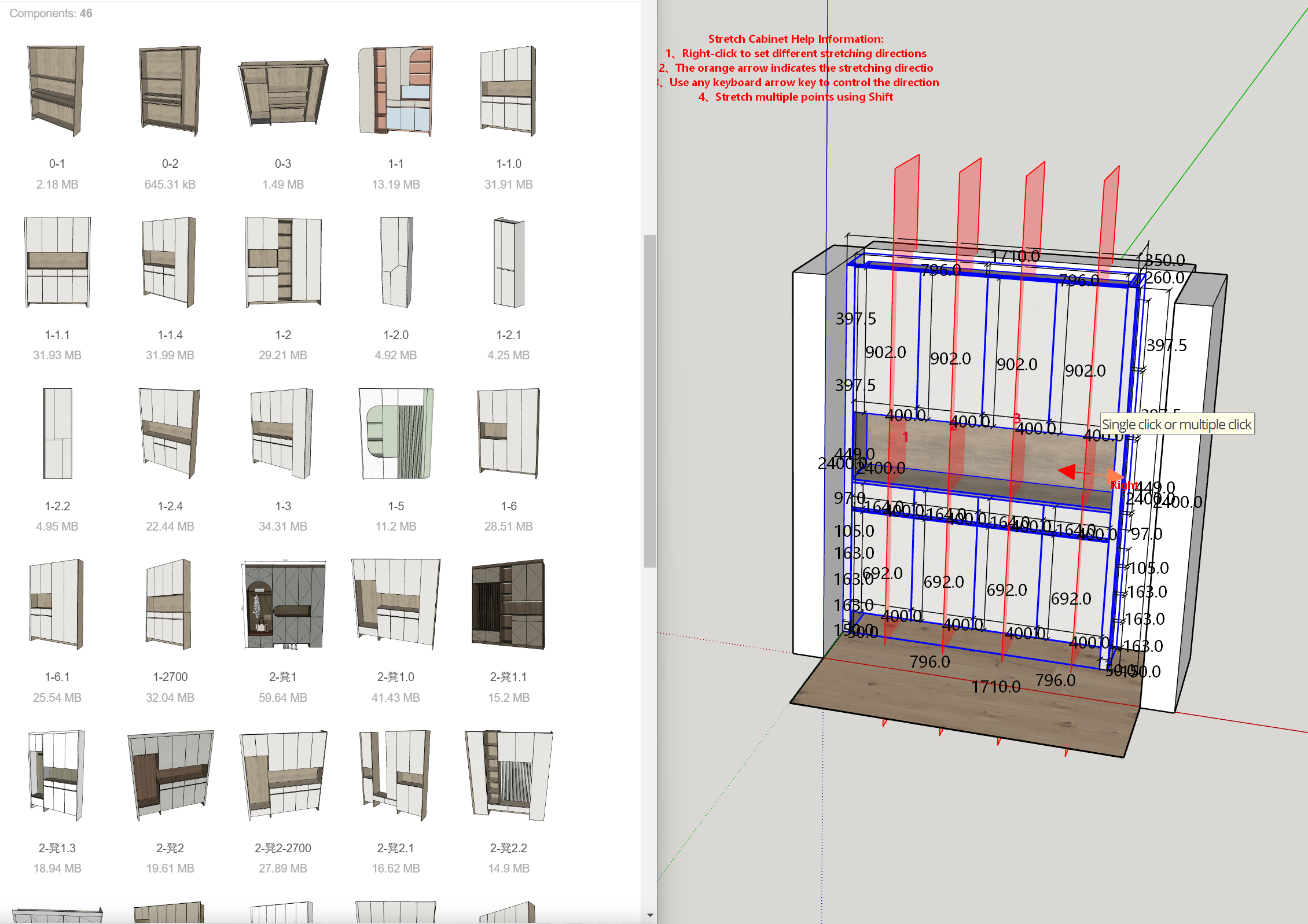

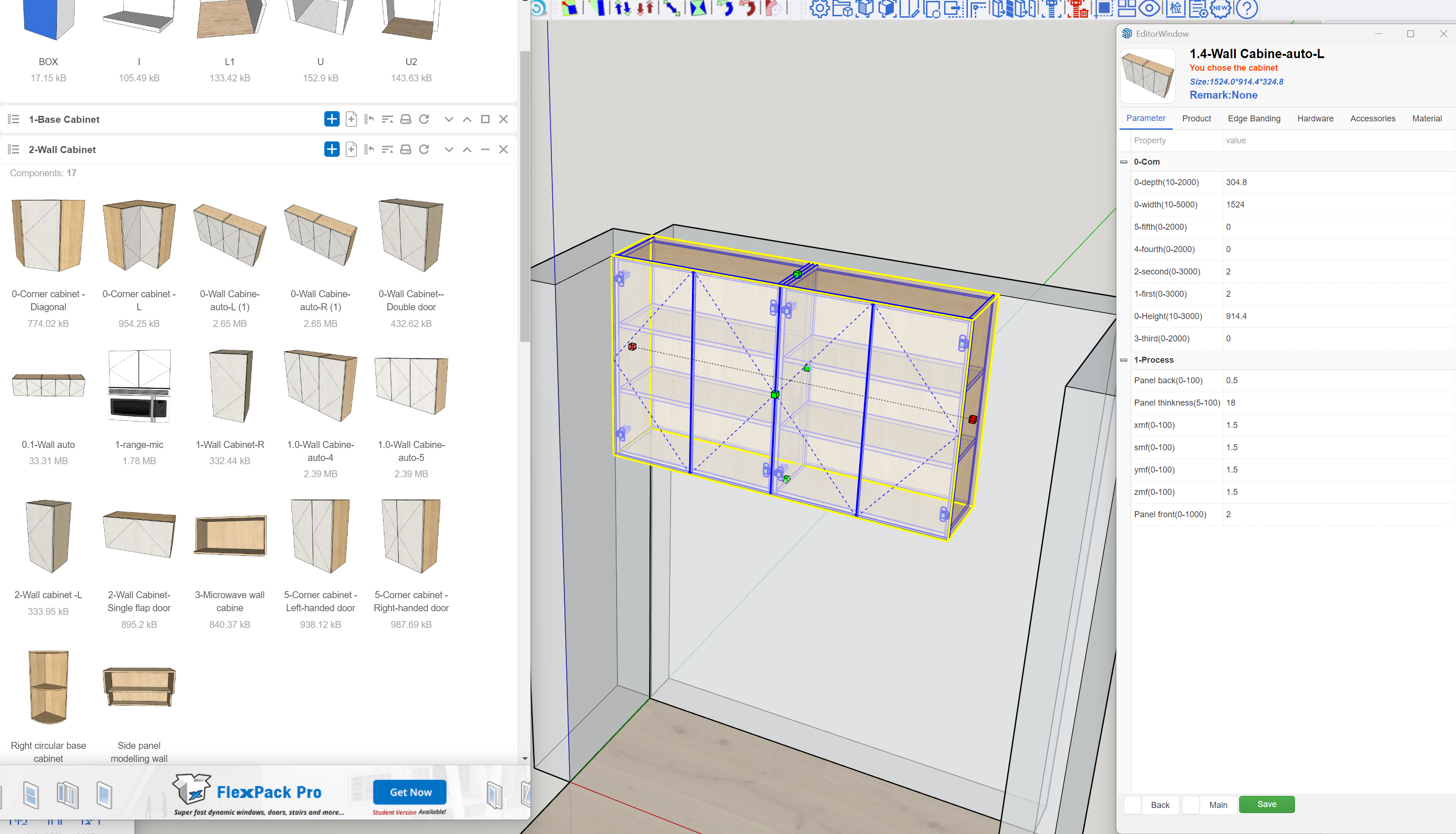

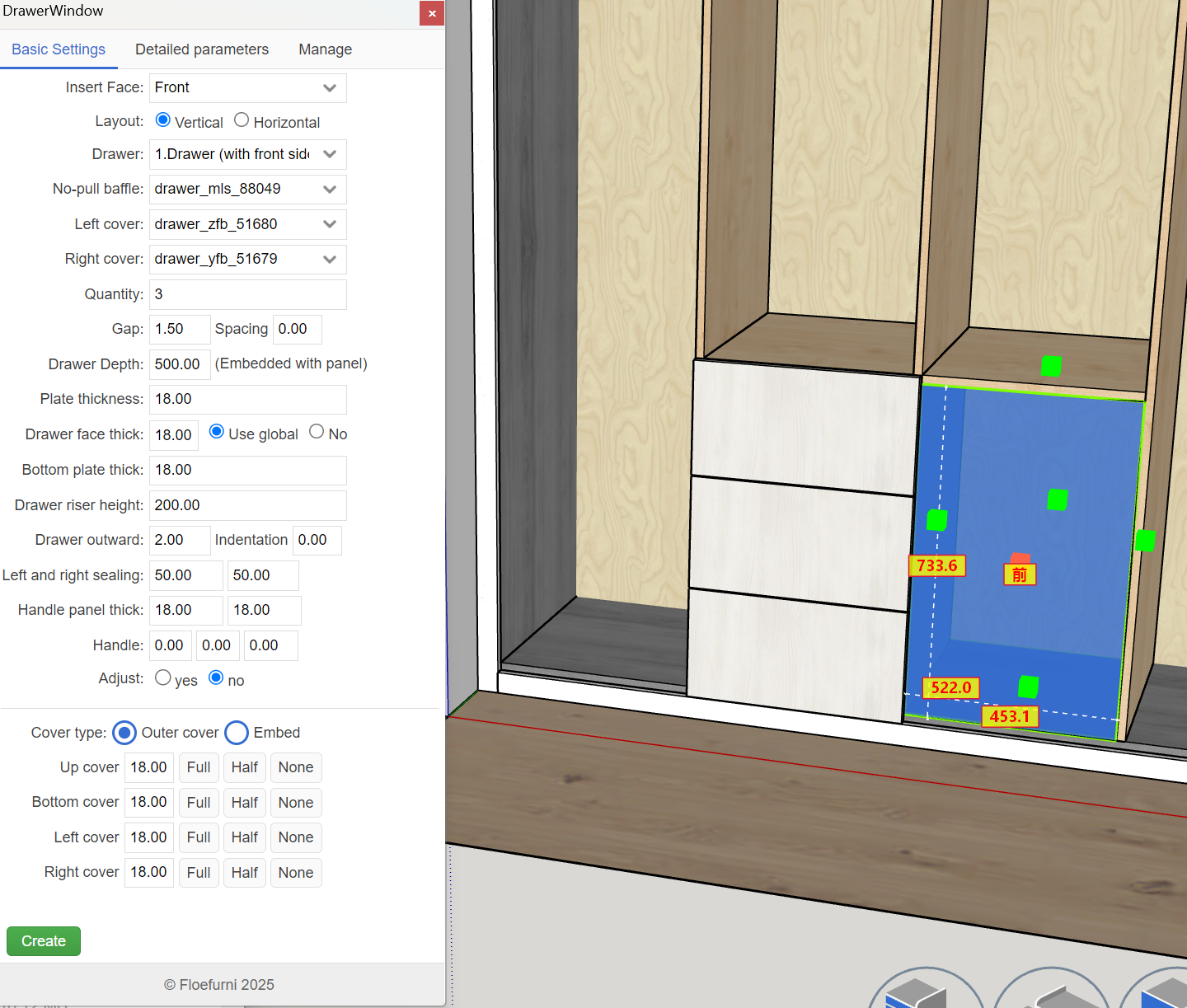

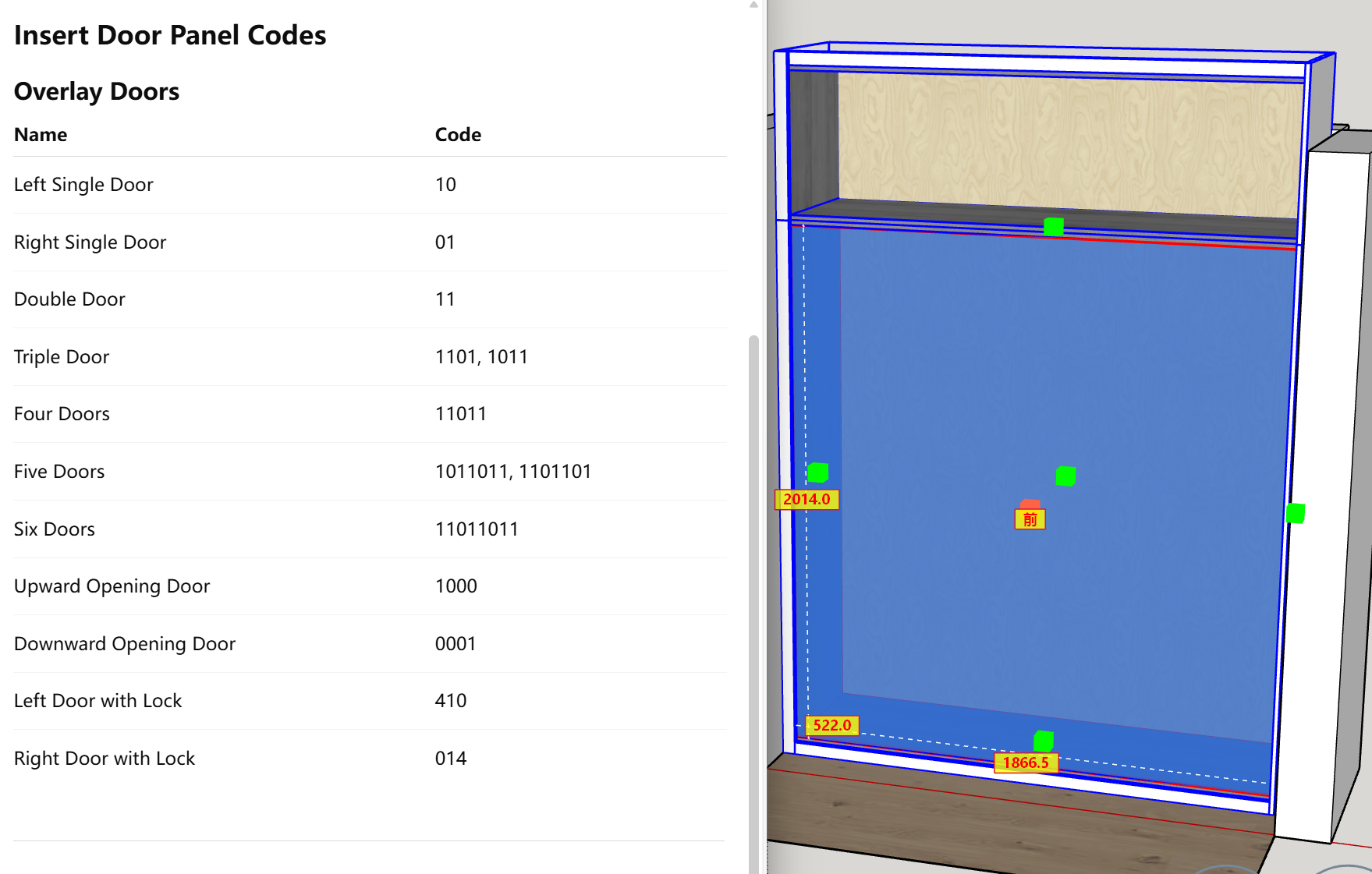

In ArchiWood every cabinet stays parametric. You can stretch, split, re-configure and save new layouts while keeping a stable, production-ready structure.

Grab one cabinet in a run and stretch it to size. Carcasses, doors, fillers and worktops all update together while ArchiWood maintains joints, reveals and drilling.

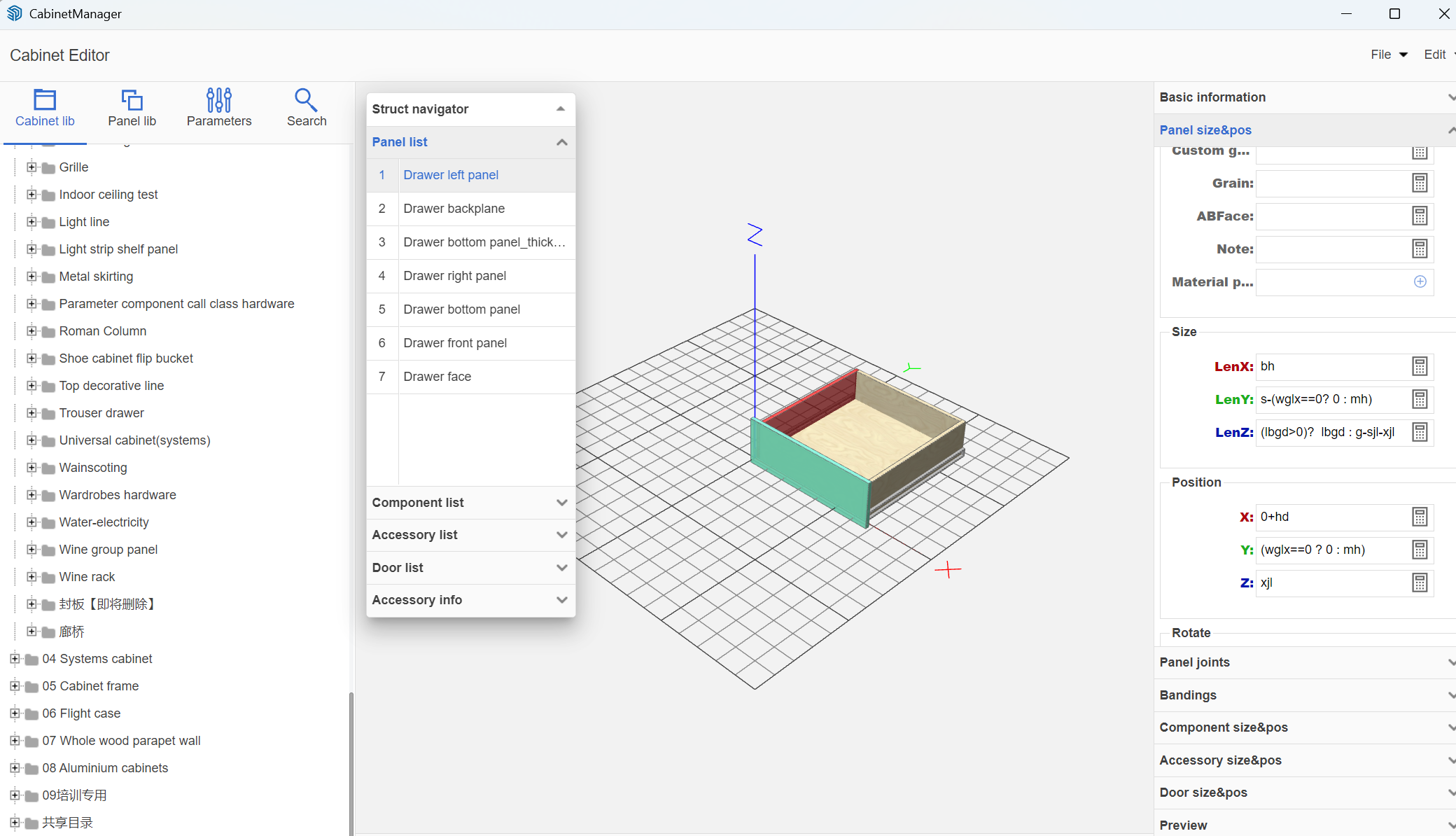

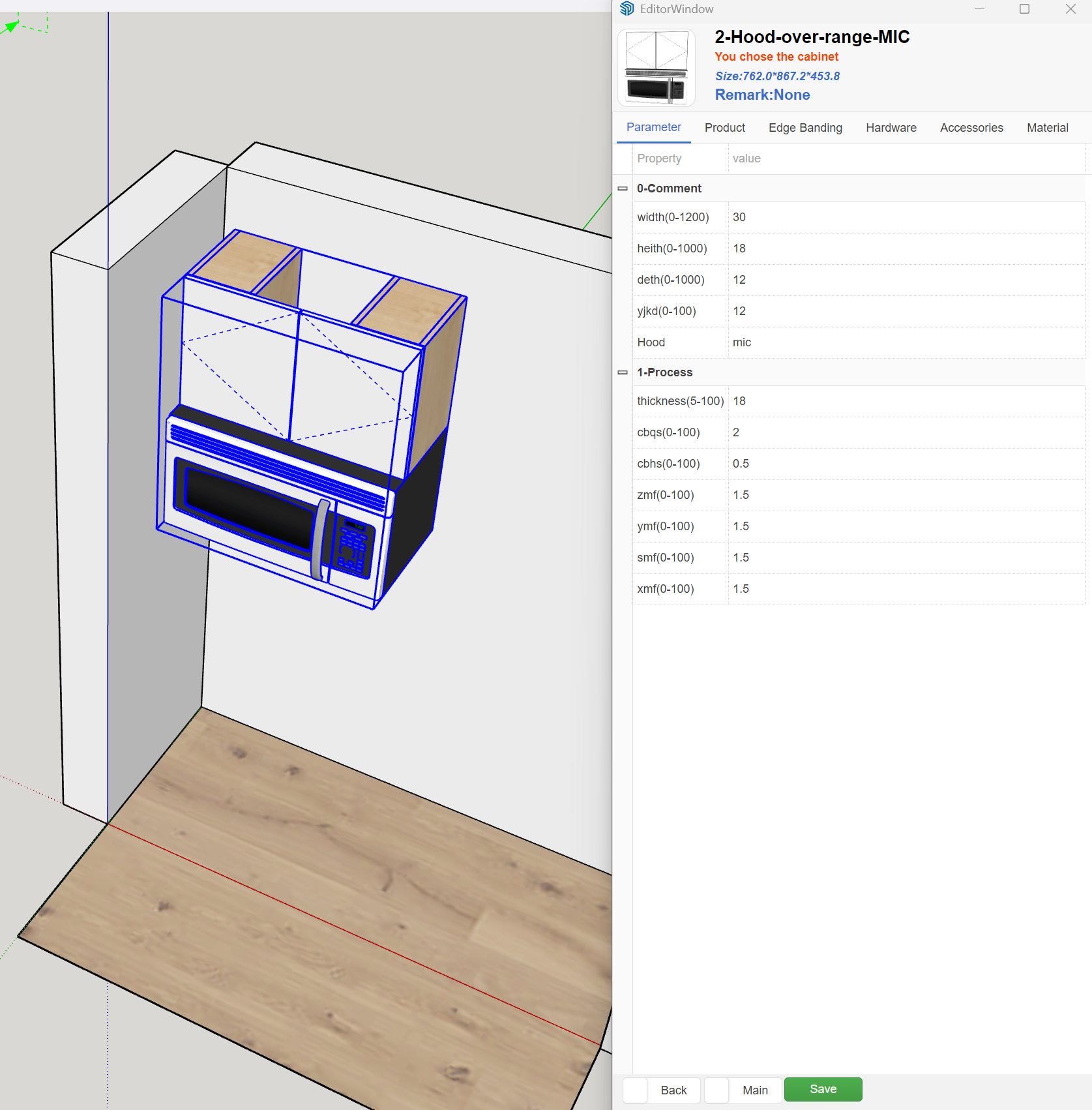

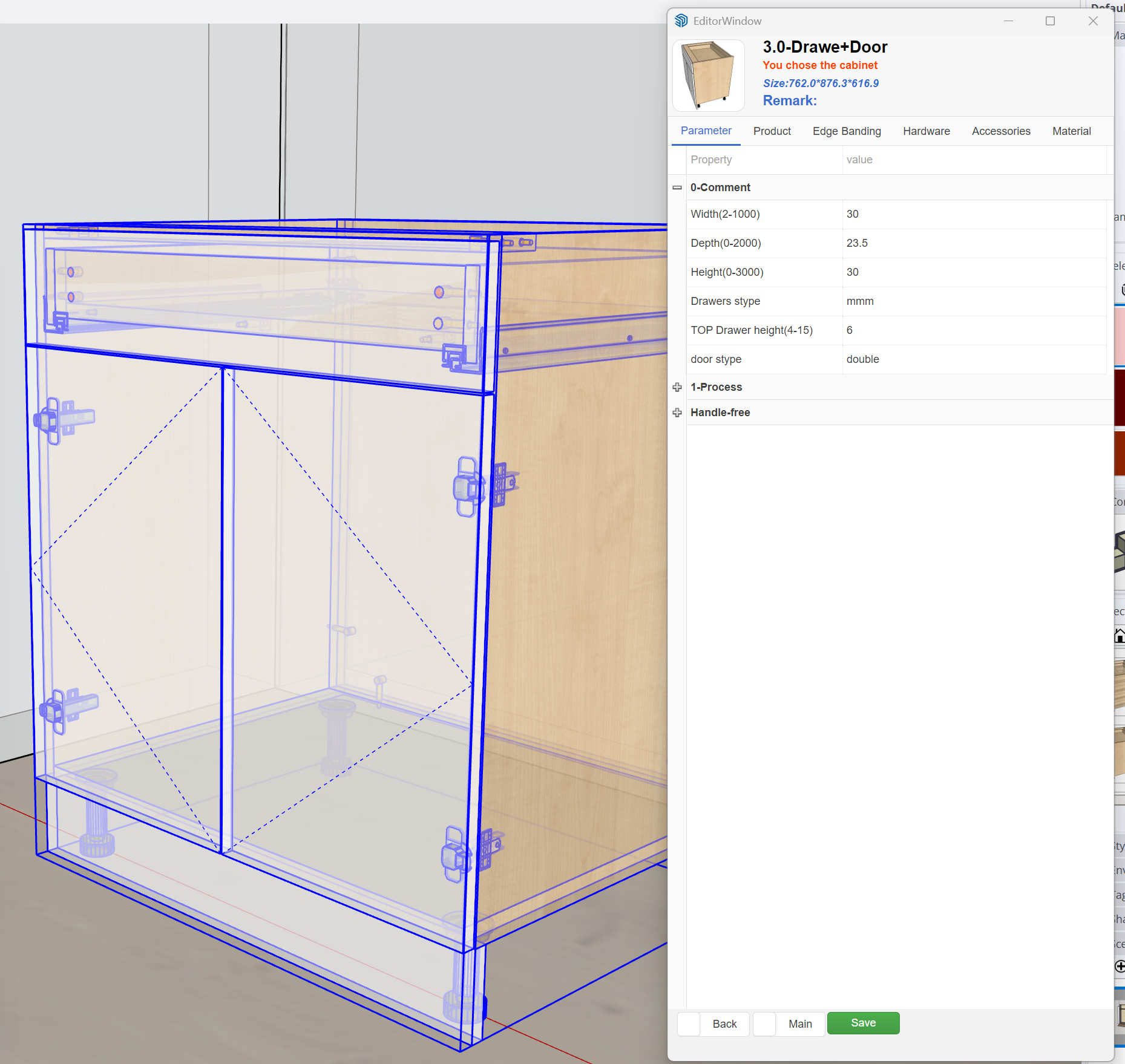

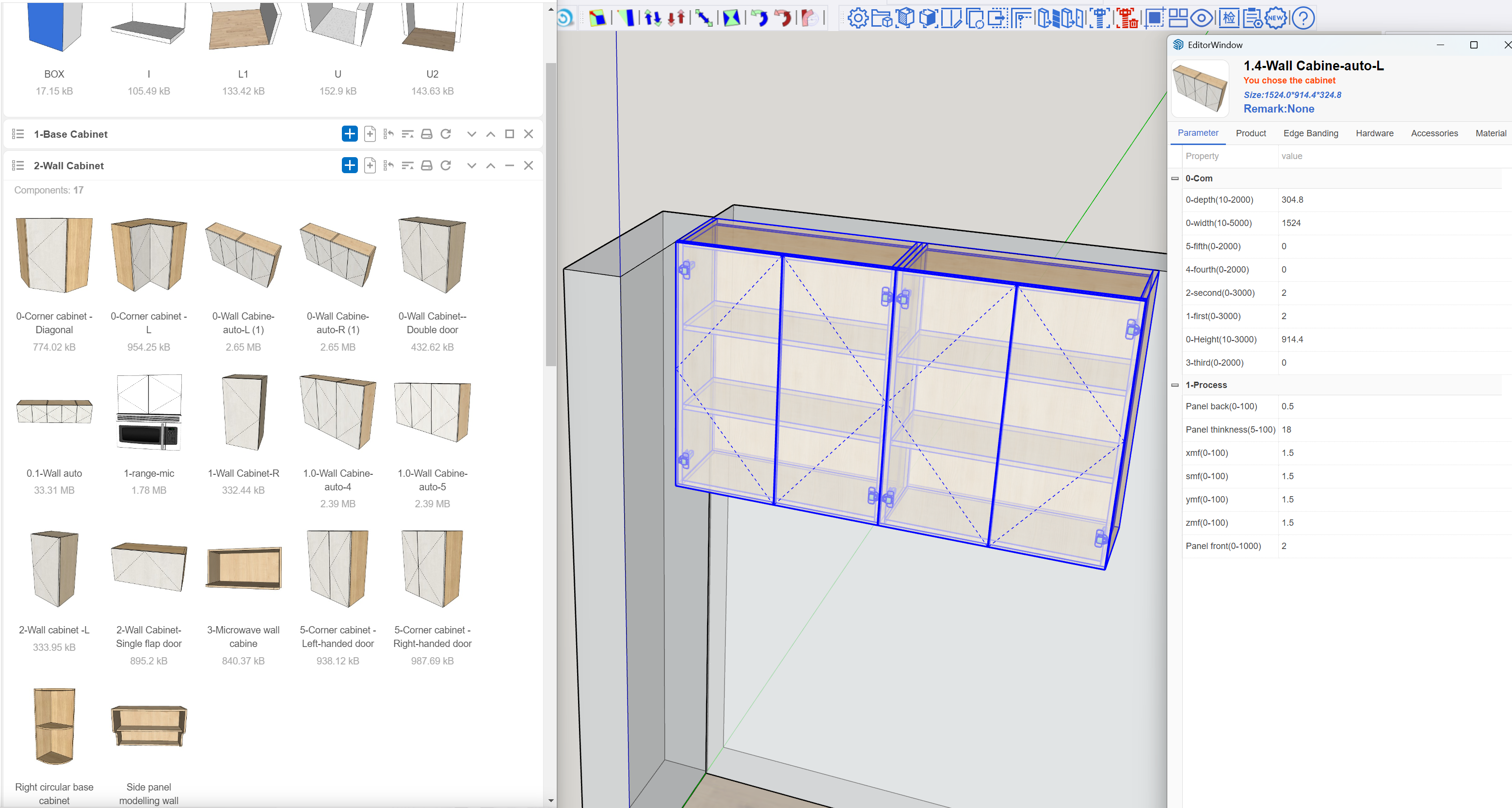

Use a single parameter panel to drive width, height, depth, toe kicks, back options and many more controls. Designers change values once – all affected parts update instantly.

Quickly insert, remove or move vertical divisions while keeping hardware rules and machining consistent.

Control drawer stacks, front splits and reveal sizes with numeric values or presets.

Quickly switch between different back panels, plinth systems, hanging rails and construction methods without rebuilding cabinets.

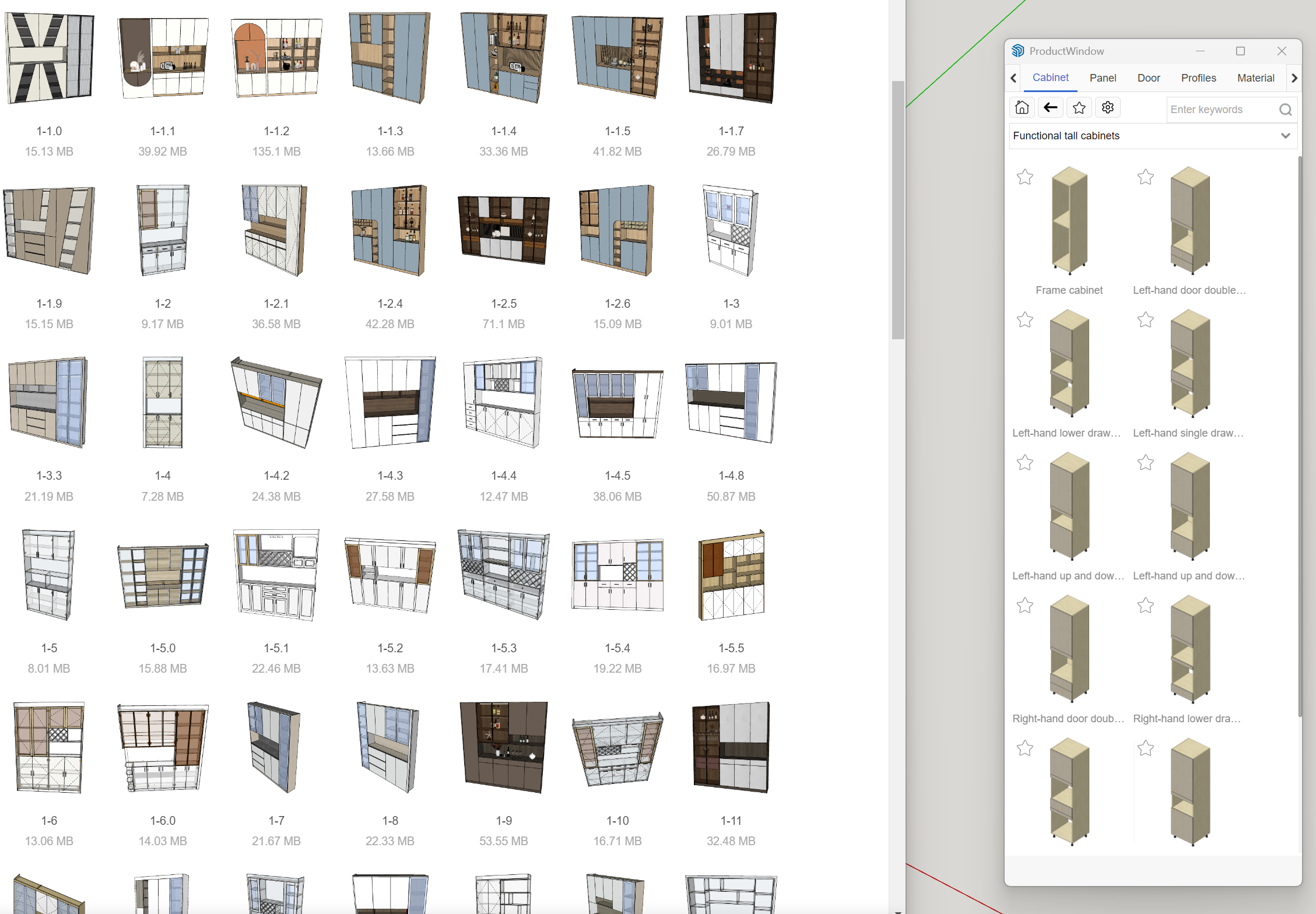

Dedicated controls for tall cabinets and utility units – shelves, internal drawers and appliances – make complex pieces just as fast to configure.

Adjust individual doors and panels – for example special reveals or hinge layouts – while keeping the underlying cabinet parametric.

ArchiWood analyses the room geometry, cabinet panels and machining rules to help you place units, fill spaces intelligently and avoid expensive mistakes before cutting a single sheet of board.

Let ArchiWood scan the room geometry and suggest appropriate cabinet modules for each gap. It can automatically populate walls, corners and niches with the right units and panels, ready for refinement.

Colour-coded hints and badges show panels that need attention – for example missing hardware, unusual machining or special materials – so you can adjust them before exporting.

Configure label layouts, QR codes and barcodes to match your production line. Every panel can carry the information operators, assemblers and installers need.

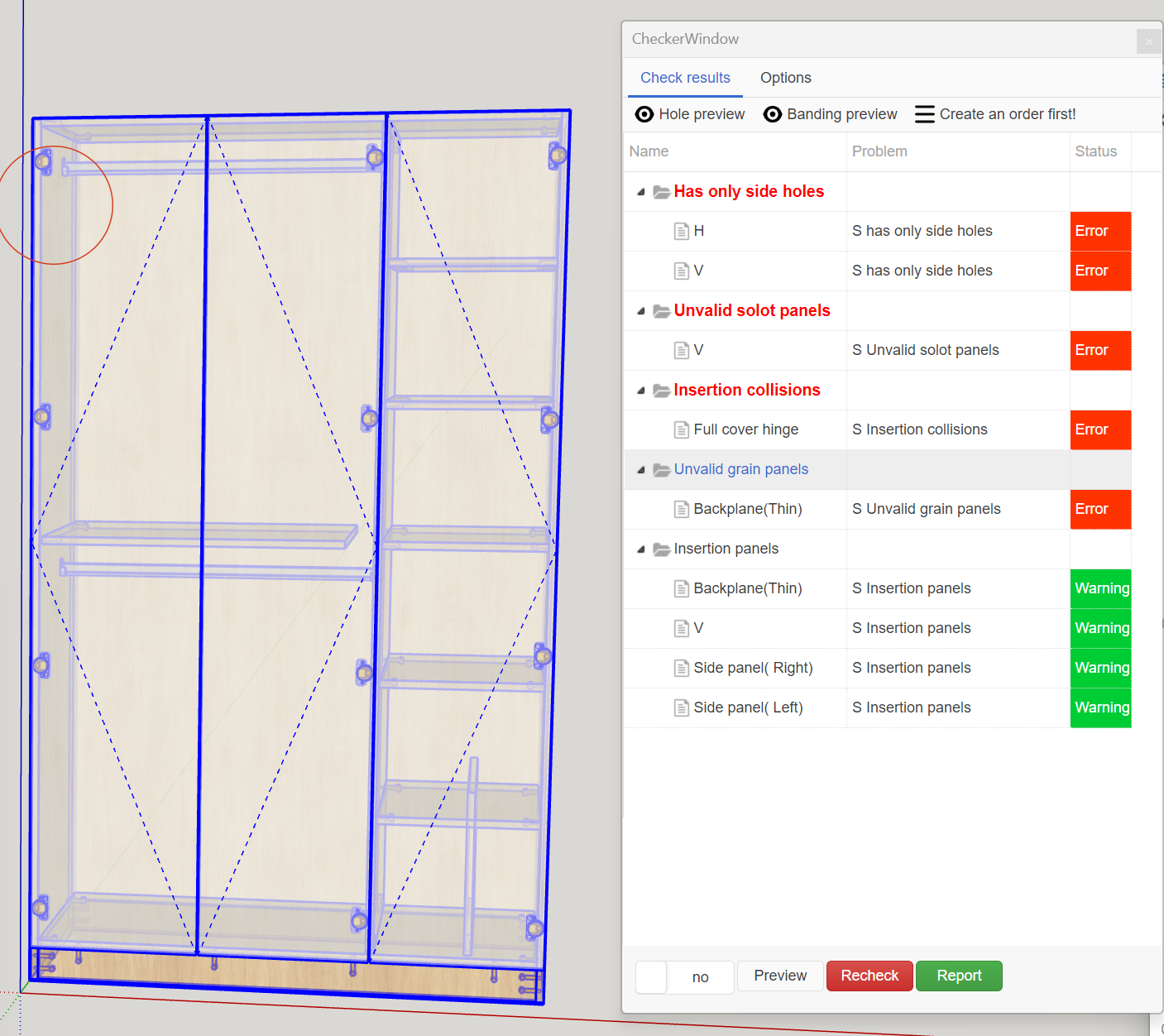

Run error detection for missing parts, impossible drilling or wrong edge-banding before releasing jobs to nesting. The system points directly to the problematic cabinets.

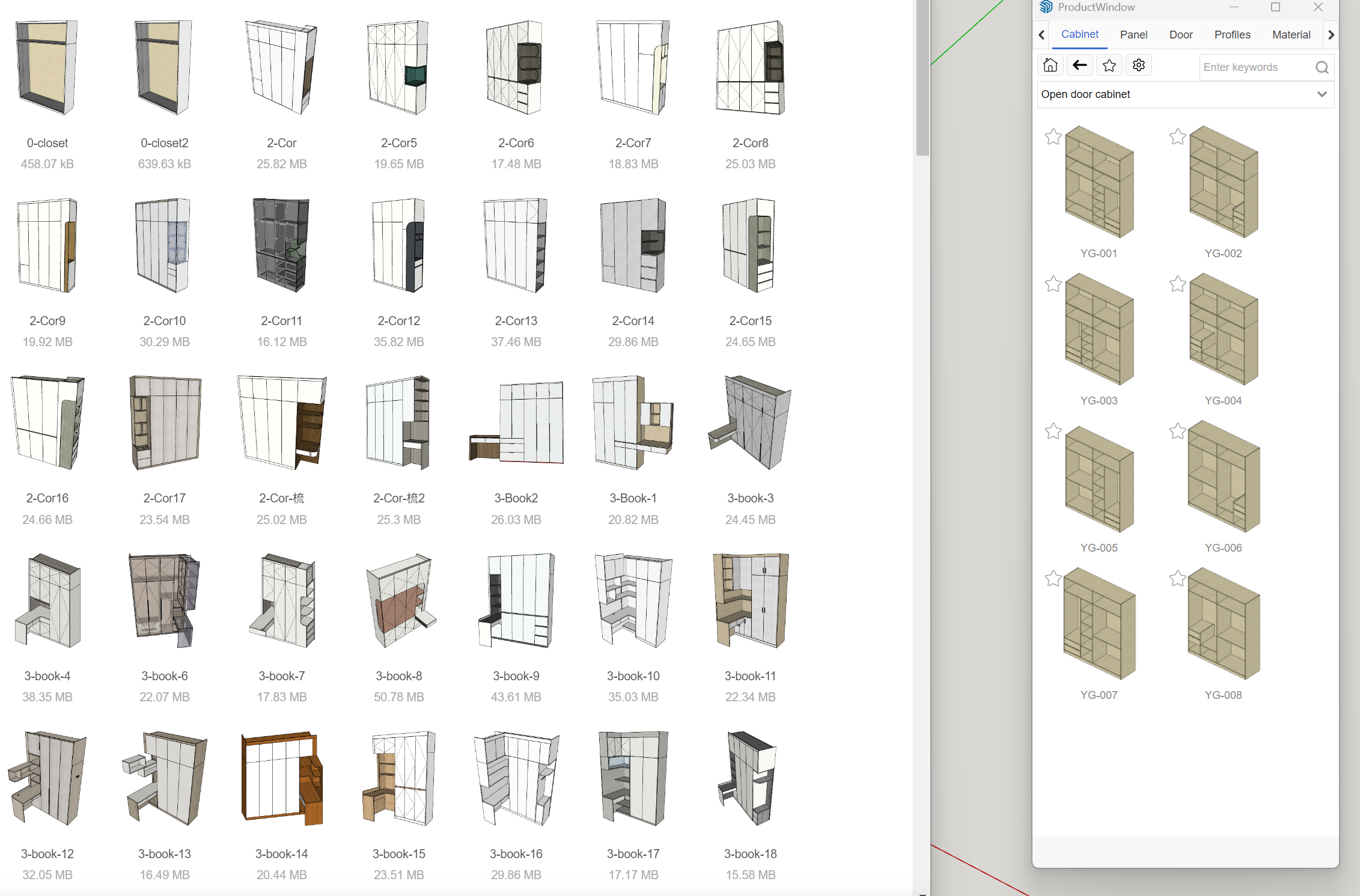

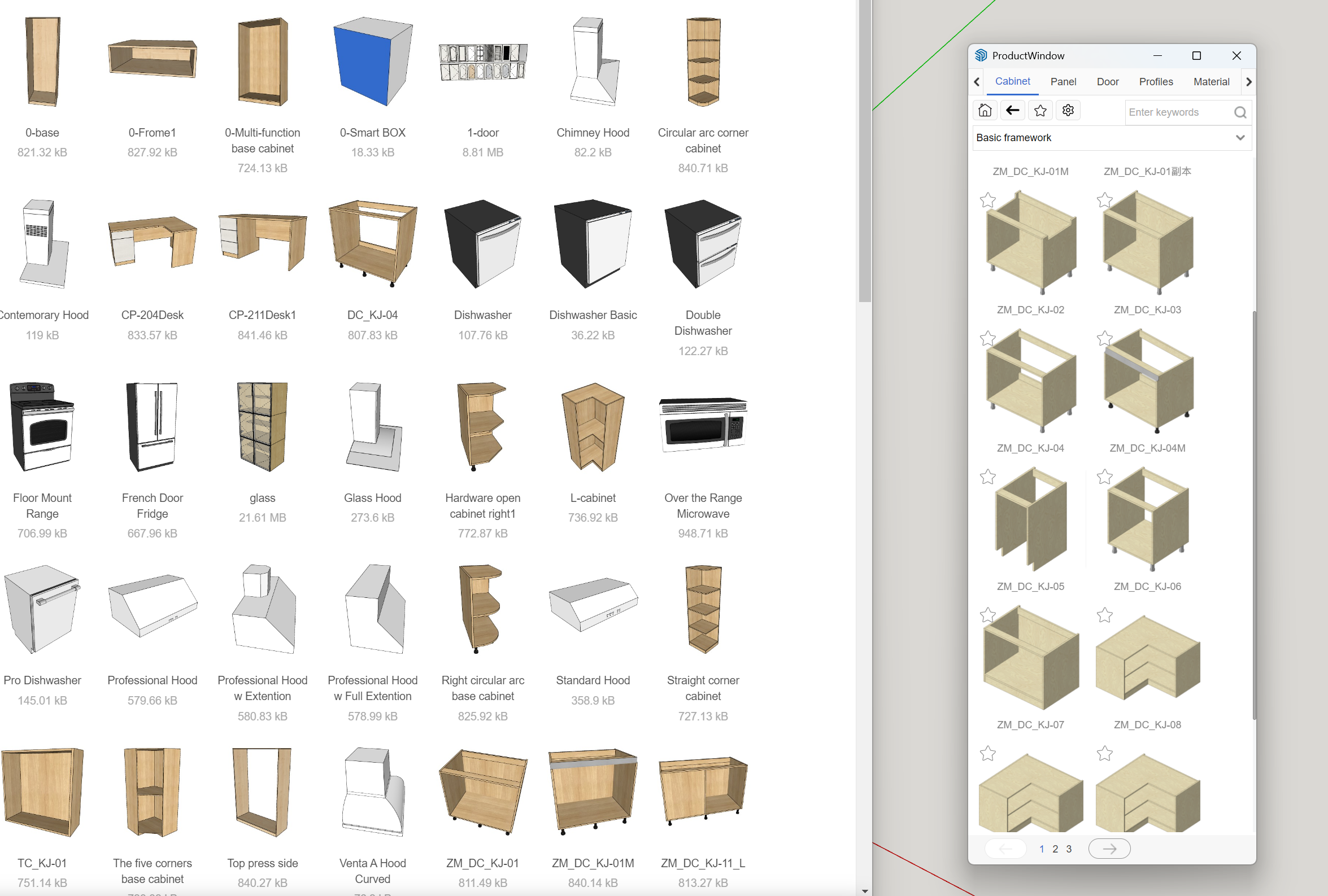

Build once, reuse forever. ArchiWood ships with ready-to-use parametric libraries and then lets you tune them to your own factory standards – cabinet structures, doors, drawers, fronts, decorative panels and more.

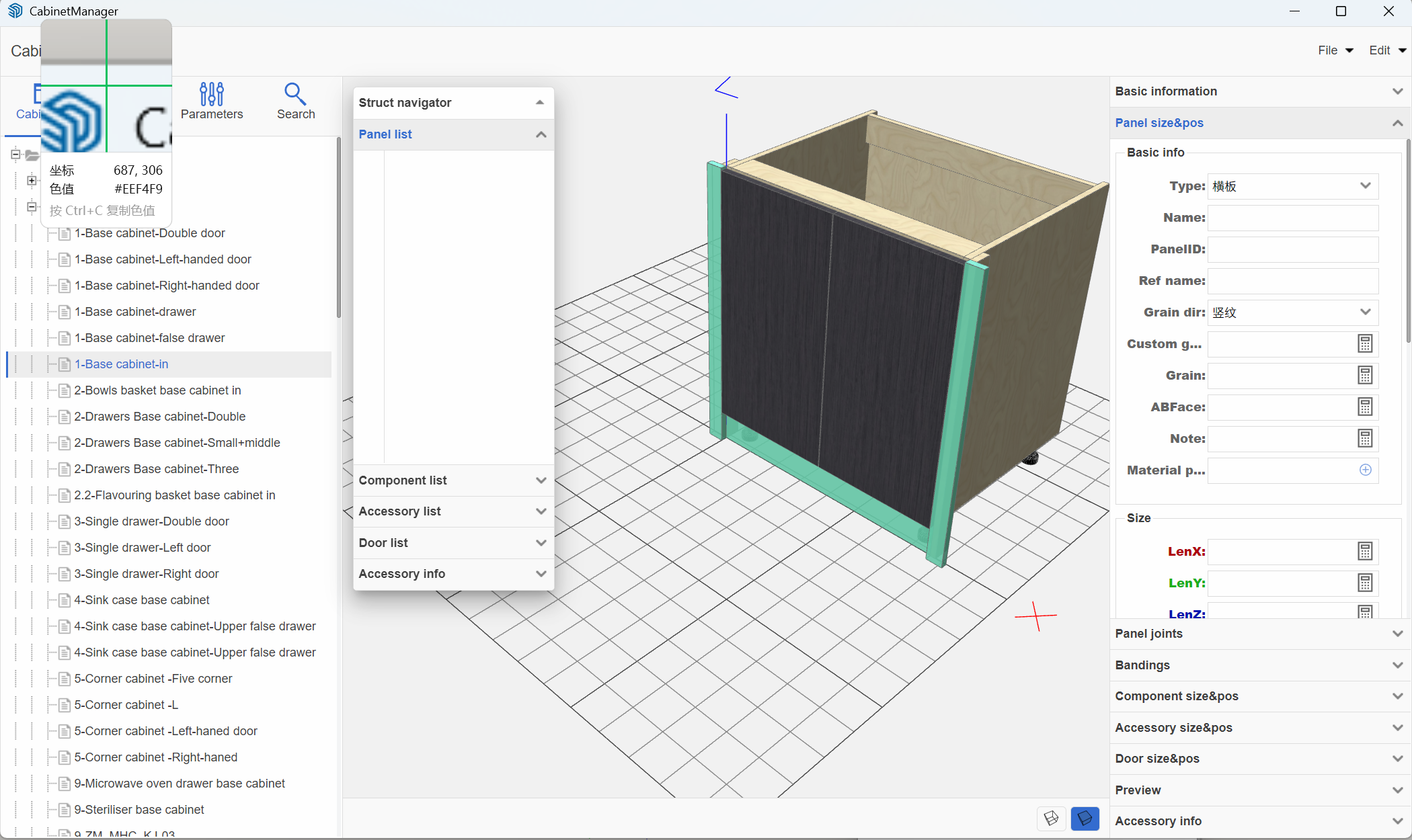

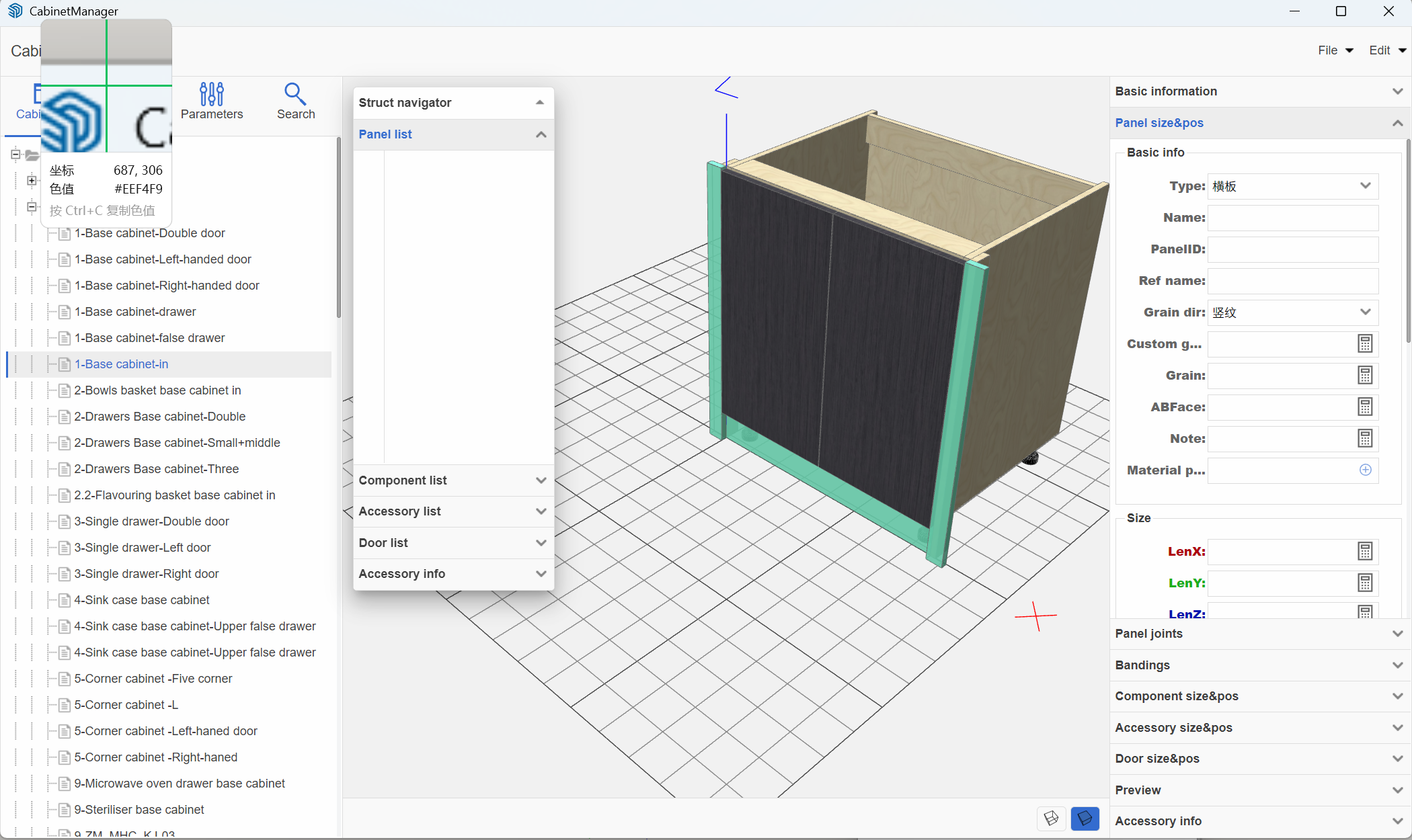

A visual library of standard kitchen and wardrobe modules you can stretch, split and re-configure without losing production logic.

Ready-to-use corner cabinets, end panels and special modules help you cover tricky spaces while keeping machining rules consistent.

Detailed components such as pilasters, trims and feature panels let you present and produce more premium designs using the same workflow.

Automatically create mortises and slots for connectors according to your hardware brand and rules. When a cabinet changes, its machining updates as well.

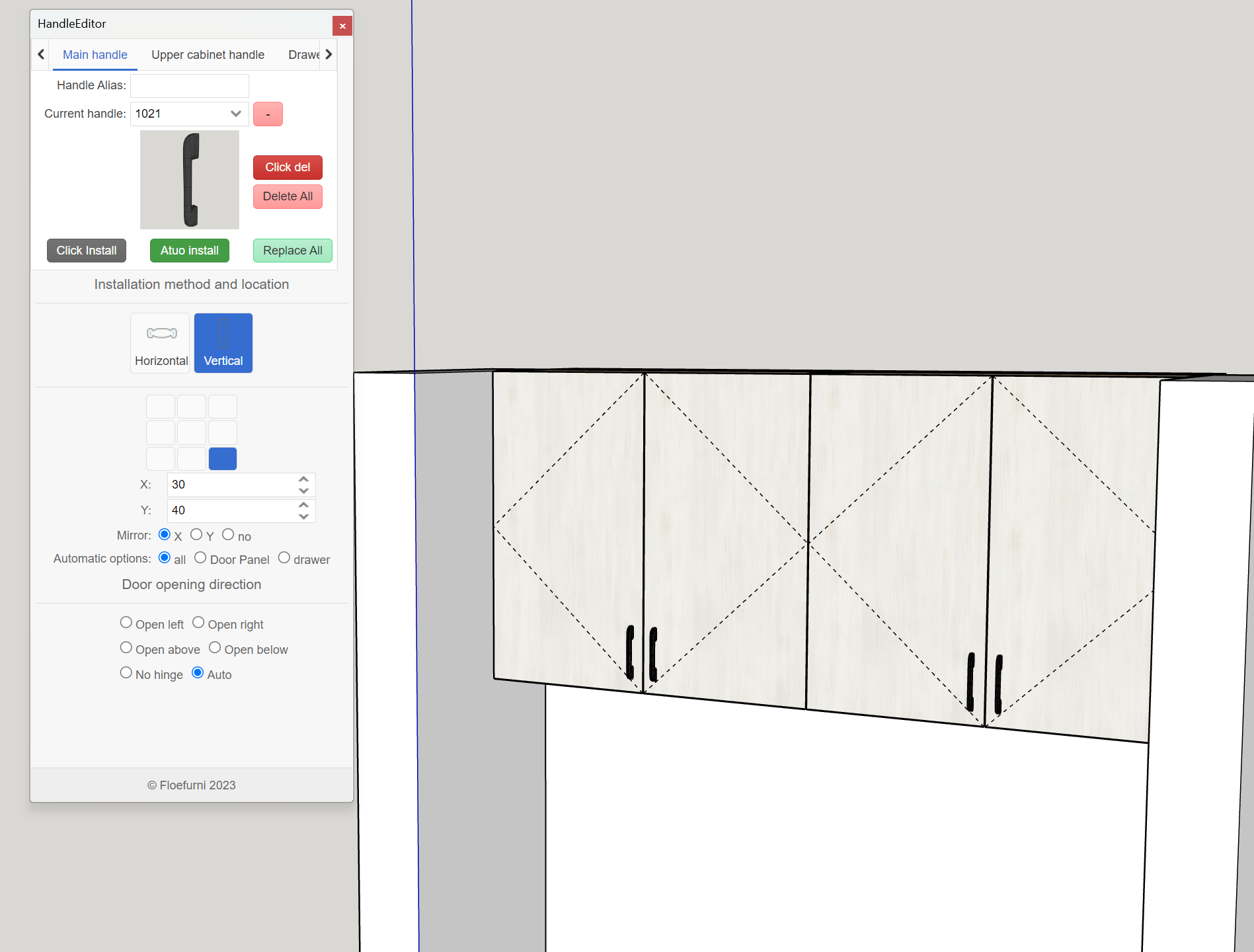

Place handles and pulls according to rules – centre, offset, vertical or horizontal – and then update them for an entire project when the client changes style.

Tell us a little about your factory or studio – location, machines, current software – and we’ll walk you through how ArchiWood can plug into your workflow: from design, through nesting, to CNC.

Use any of the channels below. We are happy to schedule a 30-minute online session and walk through a real project using your requirements.

Video tutorials and English documentation are being updated continuously. During training we usually record the sessions so your team can re-watch them later.